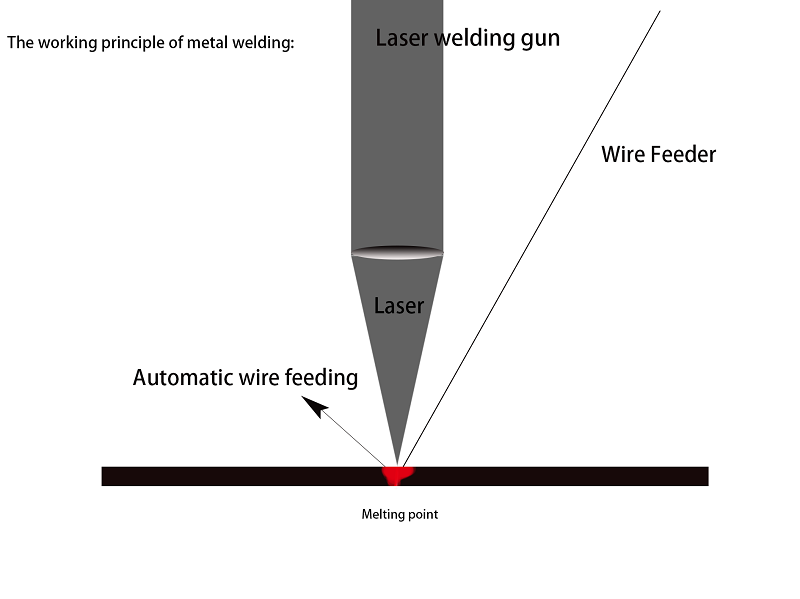

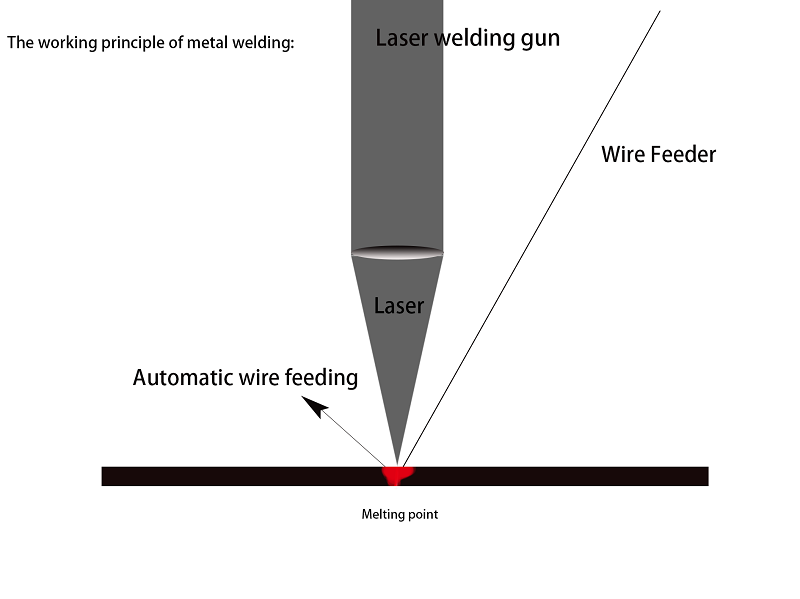

The working principle of metal welding:

Metal welding refers to a joining method in which two separate metal objects (the same or different metals) are bonded together by an appropriate method. Welding can not only solve the connection problems of various steels, but also solve the connection problems of non-ferrous metals such as aluminum and copper, and special metal materials such as titanium and zirconium. Therefore, it has been widely used in machinery manufacturing, shipbuilding, marine development, automobile manufacturing, petrochemical, aerospace technology, atomic energy, electric power, electronic technology, and construction fields. With the needs of modern industrial production and the vigorous development of science and technology, welding technology continues to develop. As far as new welding methods are concerned, there are dozens of methods so far. When choosing a welding method in production, not only must understand the characteristics and selection range of various welding methods, but also consider the requirements of the product, and then make a preliminary selection according to the structure, material and production process of the product.

The basic principle of metal welding in the figure below

How to choose a metal laser welding machine?

The following video is the working video of the metal welding machine

1. The energy of the laser pulse

The energy of the laser pulse refers to the maximum output energy of a single laser pulse, and the unit is J (Joule ). With a certain power, the higher the energy of a single laser pulse, the lower the emission frequency. The energy of the laser pulse is the main parameter of the laser, which determines the maximum energy that the laser can produce.

2. The focusing diameter of the laser spot

The focus diameter of the laser spot is an extremely important parameter reflecting the design performance of the laser. The unit is mm (millimeters), which determines the power density and processing range of the laser. If the optical design of the laser is reasonable and advanced, the laser energy is concentrated, and the focus is accurate, the laser spot diameter can be controlled within the range of 0.2mm-1.5mm, and whether the focus diameter of the laser can be controlled within 0.2mm is a strict requirement for the laser generator The test.

3. Frequency of laser pulse

The frequency of laser pulses reflects the ability of the laser to produce pulses in one second, and the unit is Hz (Hertz). Take metal welding as an example. Welding metal uses the energy of the laser. When the laser power is constant, the higher the frequency, the smaller the energy output of each laser. Therefore, we need to ensure that the laser energy is sufficient to melt the metal. In the case of, considering the processing speed, the laser output frequency can be determined. Take the hand-held laser welding machine produced by OPTIC LASER as an example. Its laser pulse frequency is 50-5000Hz and can be adjusted in stages. It can fully meet the precision welding processing of different materials and different shapes of molds. Its solder joints are smooth and beautiful, and the weld seam is smooth. Porosity, weld strength, and toughness are at least equivalent to or even more than the base metal.

What are the accessories of the metal laser welding machine?

The following figure is a part of the accessories of the metal welding machine

1. Laser: There are two main types of laser welding: CO2 gas laser and YAG solid-state laser. The most important performance of the laser is the output power and beam quality. The CO2 laser wavelength has a better absorption rate for non-metallic materials, while for metals, the YAG laser wavelength has a higher absorption rate, which is very beneficial for metal welding.

2. Beam focusing system: The laser beam focusing system is a laser and optical processing component, usually composed of several lenses. Beam focusing system and various forms: parabolic mirror system, plane mirror system, spherical mirror system.

3. Beam transmission system: The beam transmission system is used to transmit and output laser sources, including beam expansion, beam manipulation, beam energy distribution, mirror transmission, optical fiber transmission, etc.

4. Shielding gas and nozzle structure: laser welding and arc welding require inert gas protection to prevent oxidation and air pollution. Laser welding requires gas protection. In the laser welding process, these gases are output to the laser radiation area through a special nozzle to achieve a protective effect.

5. Tooling fixtures: Laser welding fixtures are mainly used to fix the welded workpieces, and make it possible to repeatedly load and unload, repeat positioning, in order to facilitate the automatic laser welding. Therefore, the fixtures are one of the essential equipment in laser welding production.

6. Observation system: Generally, the laser welding machine needs to be equipped with an observation system, which can perform real-time microscopic observation of the workpiece, which is used to facilitate accurate positioning when programming welding procedures and to inspect the welding effect during the welding process. It is generally equipped with a CCD display system or a microscope.

7. Cooling system: The cooling system provides a cooling function for the laser generator, generally equipped with a water circulation chiller with a power of 1-5 HP, (mainly for the welding machine of the square laser)

8. Cabinets, industrial computers

What are the advantages of a metal laser welding machine?

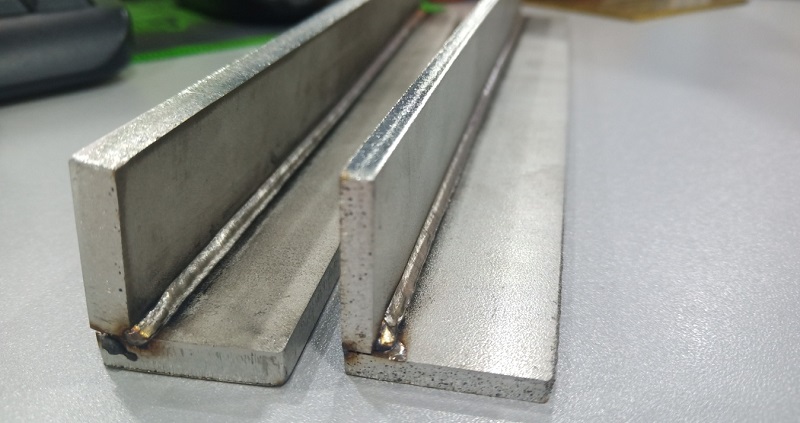

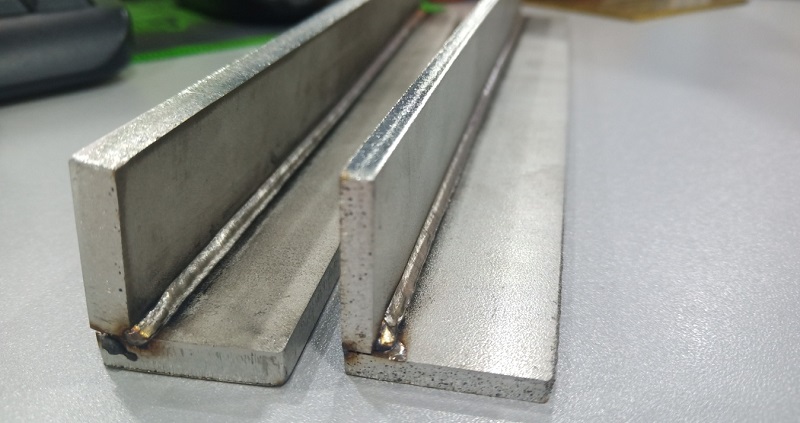

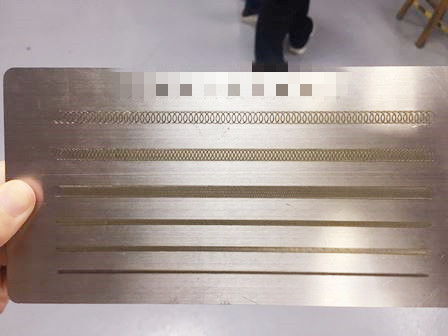

The picture above is the sample after welding steel by metal welding machine

Simple operation, no need for professional welding technical experience, simple training can be used for 2 hours.

The welding speed is super fast, and a handheld laser welder can basically replace the output of 3 to 5 ordinary welders.

Welding can be done basically without consumables, saving costs in production.

After the welding is completed, the weld is smooth and white, and it can basically be done without grinding.

The laser welding machine has concentrated energy, small heat reflection range, and the product is not easy to deform.

The laser welding machine has concentrated energy and high welding strength.

The energy and power of the laser welding machine are digitally controlled, which can meet various welding requirements, such as complete penetration, penetration, spot welding, and so on.

To sum up, the laser welding machine can completely replace the traditional welding equipment. Hand-held laser welding has the advantages of simple operation, fast welding speed, beautiful and bright white welding seam, etc., and has been well received in the market.

The function of the metal laser welding machine?

The picture below is a metal crack before metal welding machine processing

The metal welding machine can perform deposition, sealing, repair, and repair functions on the wear, scratches, pinholes, cracks, defect deformation, hardness reduction, sand holes, and other defects of the mold and metal, and can perform precision on some thin-walled materials and parts. Welding, spot welding, butt welding, stitch welding, sealing welding can be realized

Which parts of the metal laser welding machine are easily damaged?

The picture below is a picture of the metal welding machine in the production workshop

Different welding machines have different accessories.

A metal laser welding machine can generally be used for 100,000 hours. Note that it does not include the high-reflective materials you often weld, but it is inevitable that some customers will use them to weld some high-reflective alloy materials such as aluminum and copper.

Compared with the traditional YAG welding machine, the metal laser welding machine has fewer wearing parts and is not easy to break. Generally, companies will take special care of customers.

Pay attention to the maintenance and use environment of the machine, then this machine can accompany you for a long, long time. This is the conclusion that we have served many foreign customers.

How does the metal laser welding machine work?

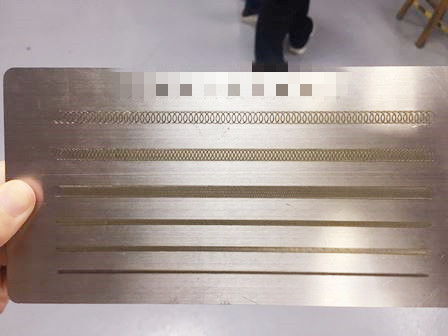

The picture above is the welding effect of the metal welding machine

The handheld laser welding machine uses high-energy laser pulses to locally heat a small area of the material. The energy of the laser radiation diffuses into the material through heat conduction, and the material is melted to form a specific molten pool. It is a new type of welding method, mainly for the welding of thin-walled materials and precision parts. It can realize spot welding, butt welding, stitch welding, sealed welding, etc., with high depth ratio, small weld width, small heat-affected zone, and deformation Small, fast welding speed, smooth and beautiful welding seam, no need to handle or simple processing after welding, high welding seam quality, no air holes, precise control, small focus spot, high positioning accuracy, easy to realize automation.

Metal Laser welding machine environment What are the requirements?

1) Temperature: The environment where the temperature exceeds the range of 0°C to +50°C (no freezing and condensation)

2) Relative humidity: 30~80% (no condensation)

3) There is ventilation equipment, no strong vibration, no heating element around

4) Clean and dust-free

5) Places with impact or severe vibration, near walls with poor ventilation, unstable and inclined places, places where static electricity, magnetism, noise, etc. may occur, near water, oil, steam, chemicals, corrosive gases , Flammable gas, iron powder, dust and other places where it may be contaminated by foreign objects such as metal or wood chips. Will have varying degrees of impact on the equipment, and even some may have safety hazards.

If you want to get more information, please contact me

English

English