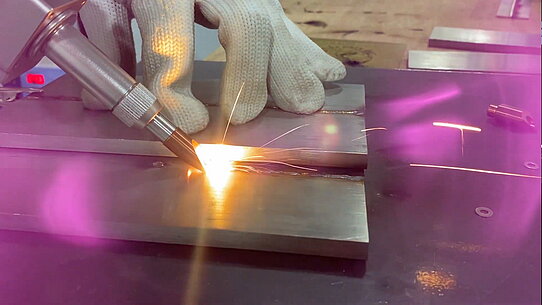

HANDHELD FIBER LASER WELDING MACHINE 2000W WITH AUTO WIRE FEEDER CNC Fiber Laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, nickel, titanium and other metals or alloys, can also be used for a variety of welding between different materials, such as: copper – brass, titanium –gold, Titanium – molybdenum, nickel – copper and so on. Welding range: 0.5~8mm carbon steel,0.5~4mm stainless steel, aluminium alloy 0.5~6mm, brass 0.5~4mm.

Stainless Steels | Carbon Steels | Gold & Silver | Aluminum Tool Steels | Nickel Alloys | Brass & Copper | Titanium

The advantage of laser welding wobble head

1. The process that the conventional head can not complete, the dithering head only needs to use about 70% of the power, so that the cost of the laser can be saved;

2 Wobble welding back and forth through the galvanometer motor, so that the bubbles with large impurities can reduce bubbles, frying, splashing, etc.

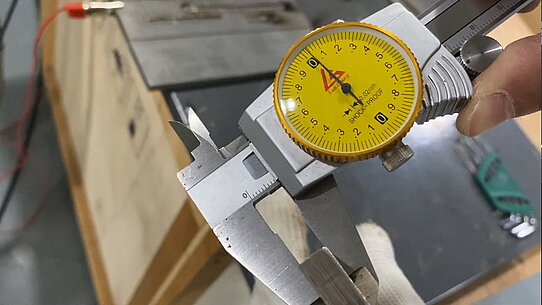

3 In the case of irregular gaps, the requirements for the fixture can be reduced. The conventional oscillating head welding gap is generally 0.2 mm, and light exceeding this width directly passes through. The width of the gap that can be welded by the oscillating head can reach 0.5mm, but the conventional welding head can only be welded to 0.2mm. There is no galvanometer motor in the welding head, so there is no swing. The welding effect is not good, the welding process is limited.

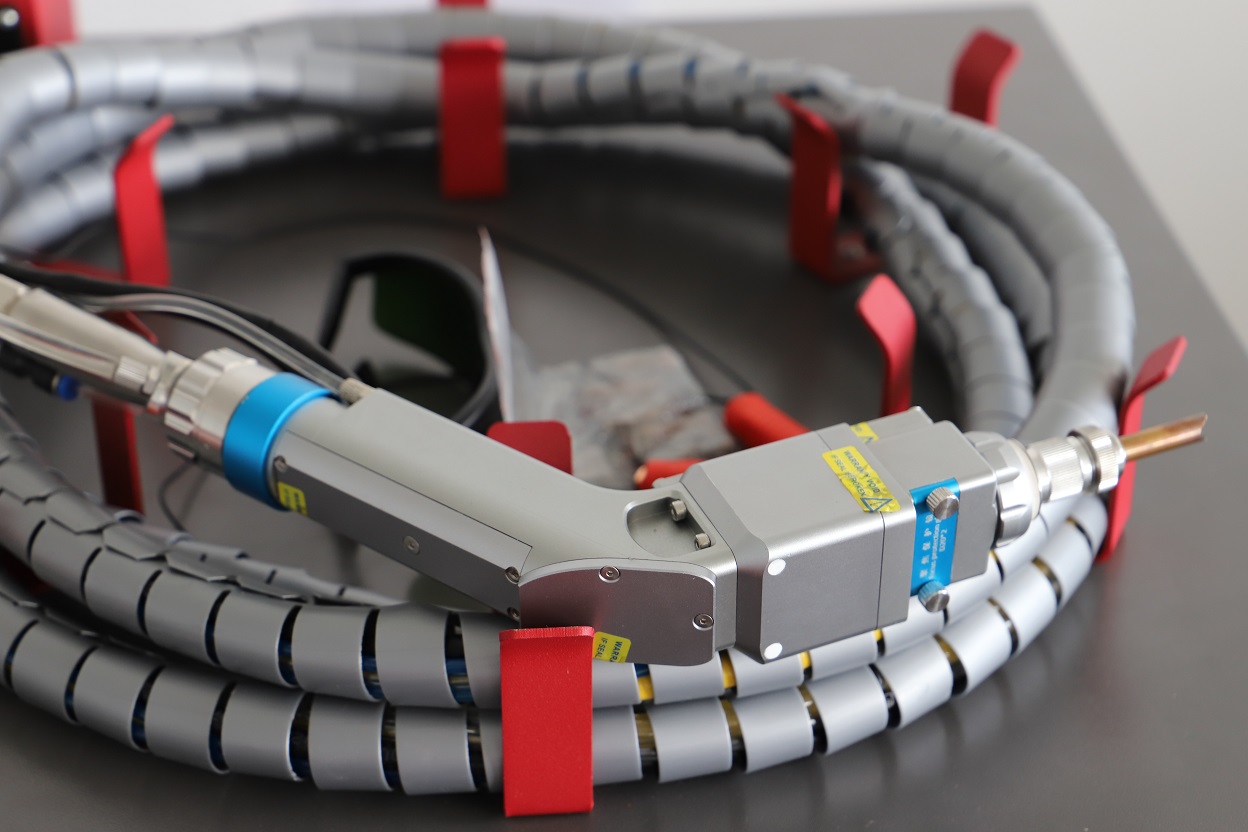

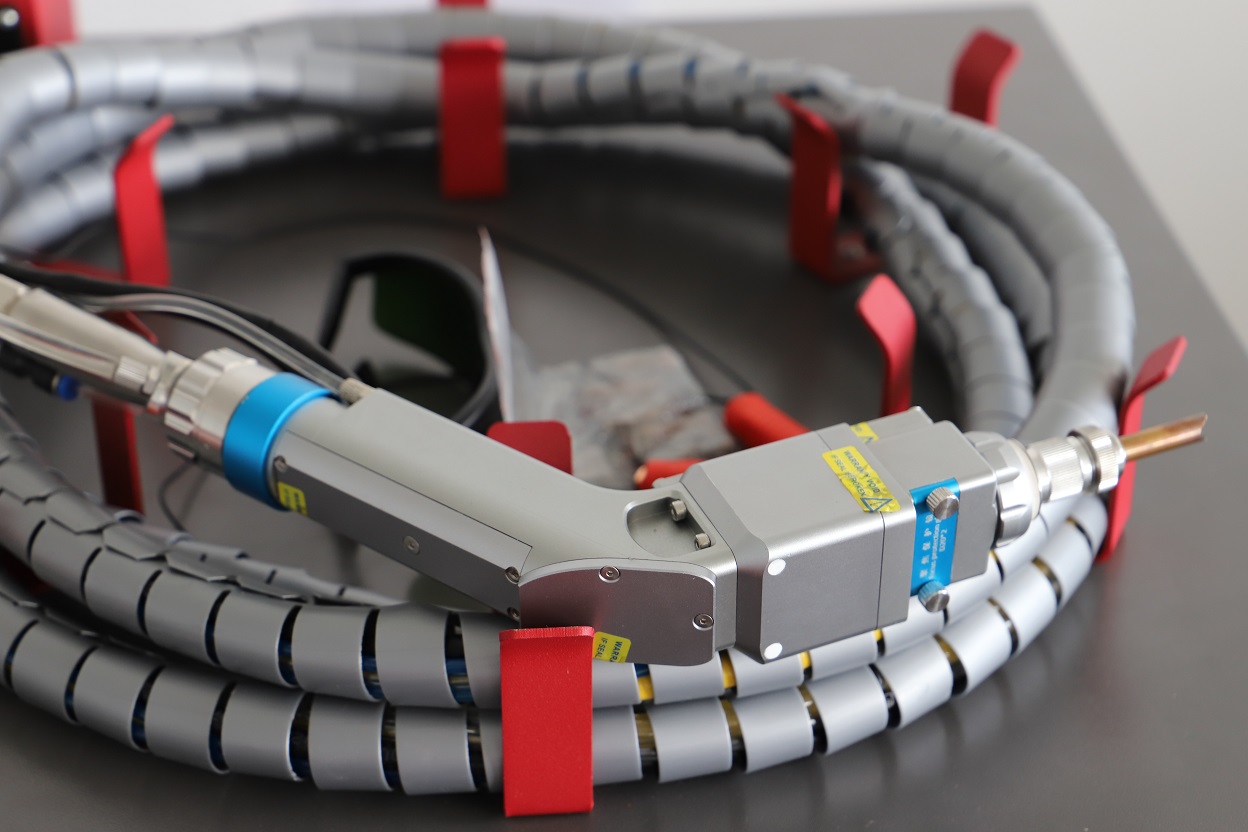

Protection System

The red part with black color is protection device when the machine welding on metal. If the safety device didn't clamp what do you weld metal,the laser power can not coming. So it have to clamp the metal as you welding that one. The laser power can coming out.

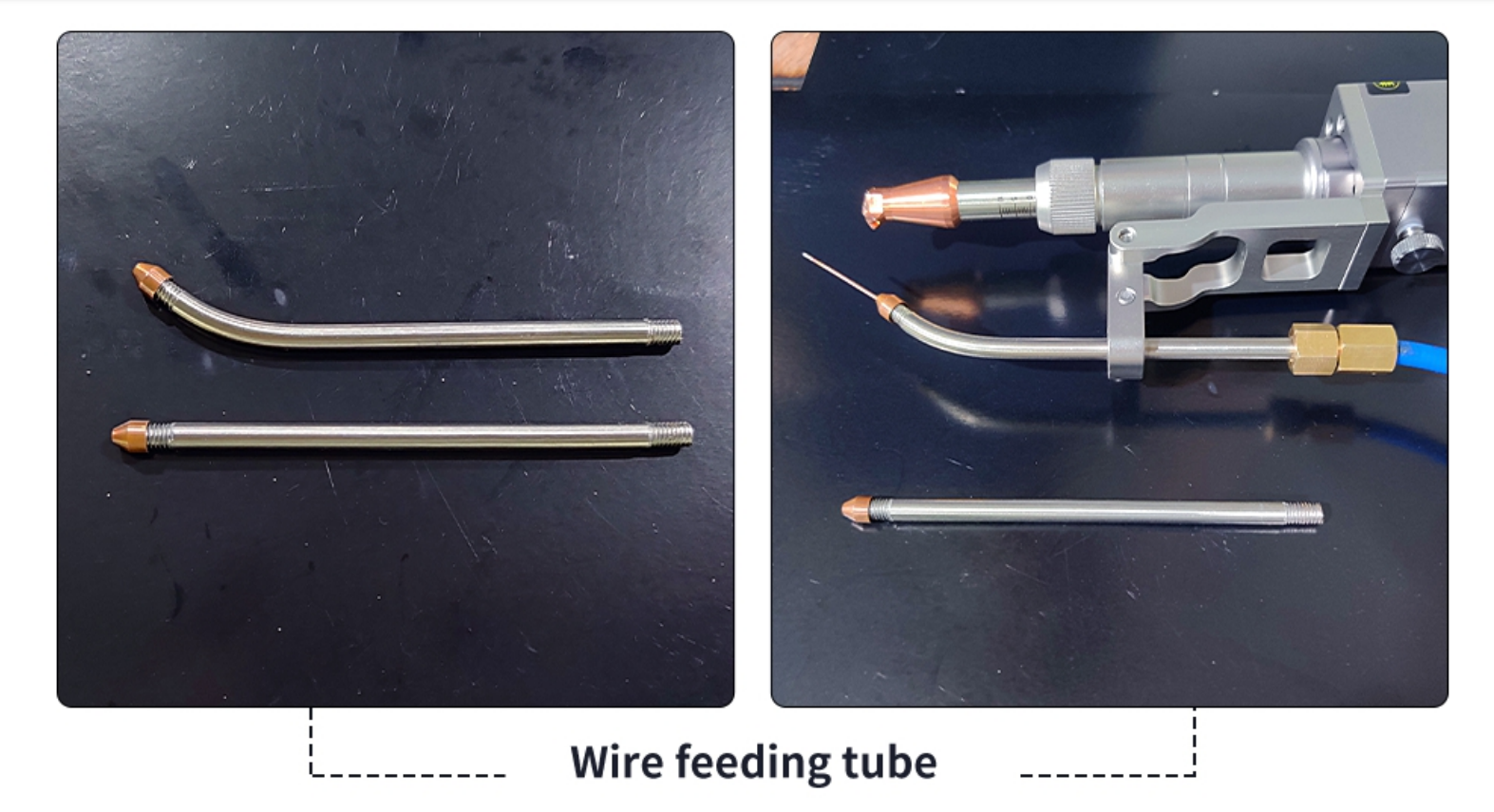

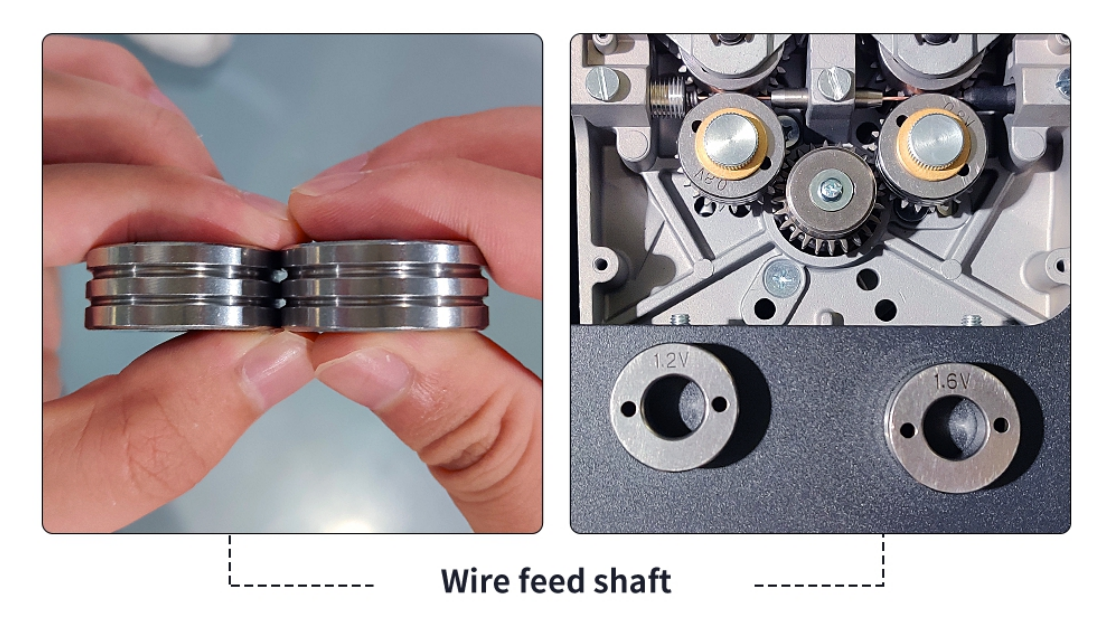

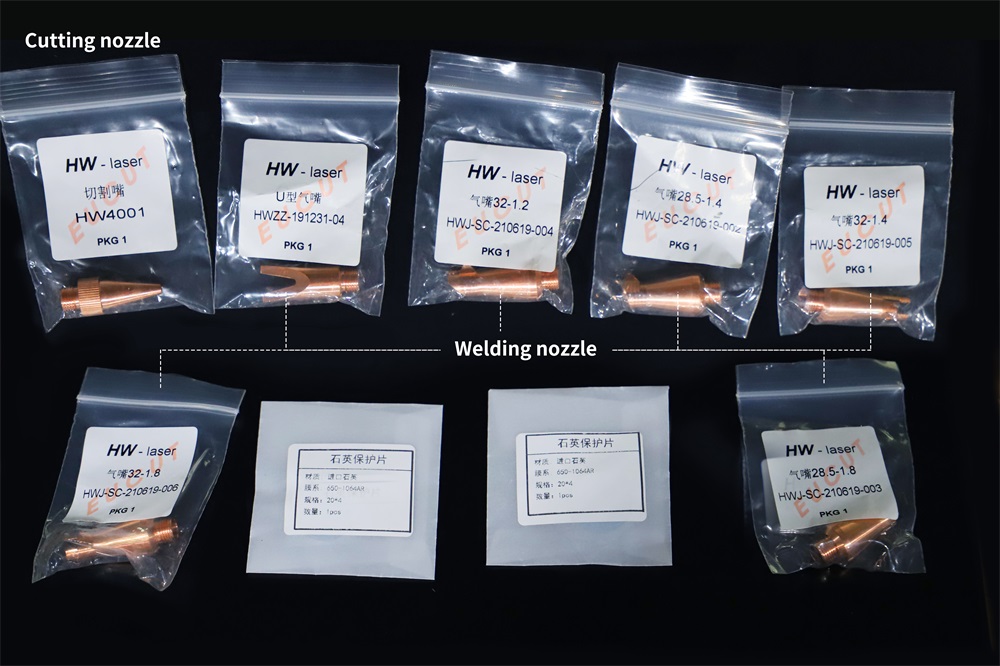

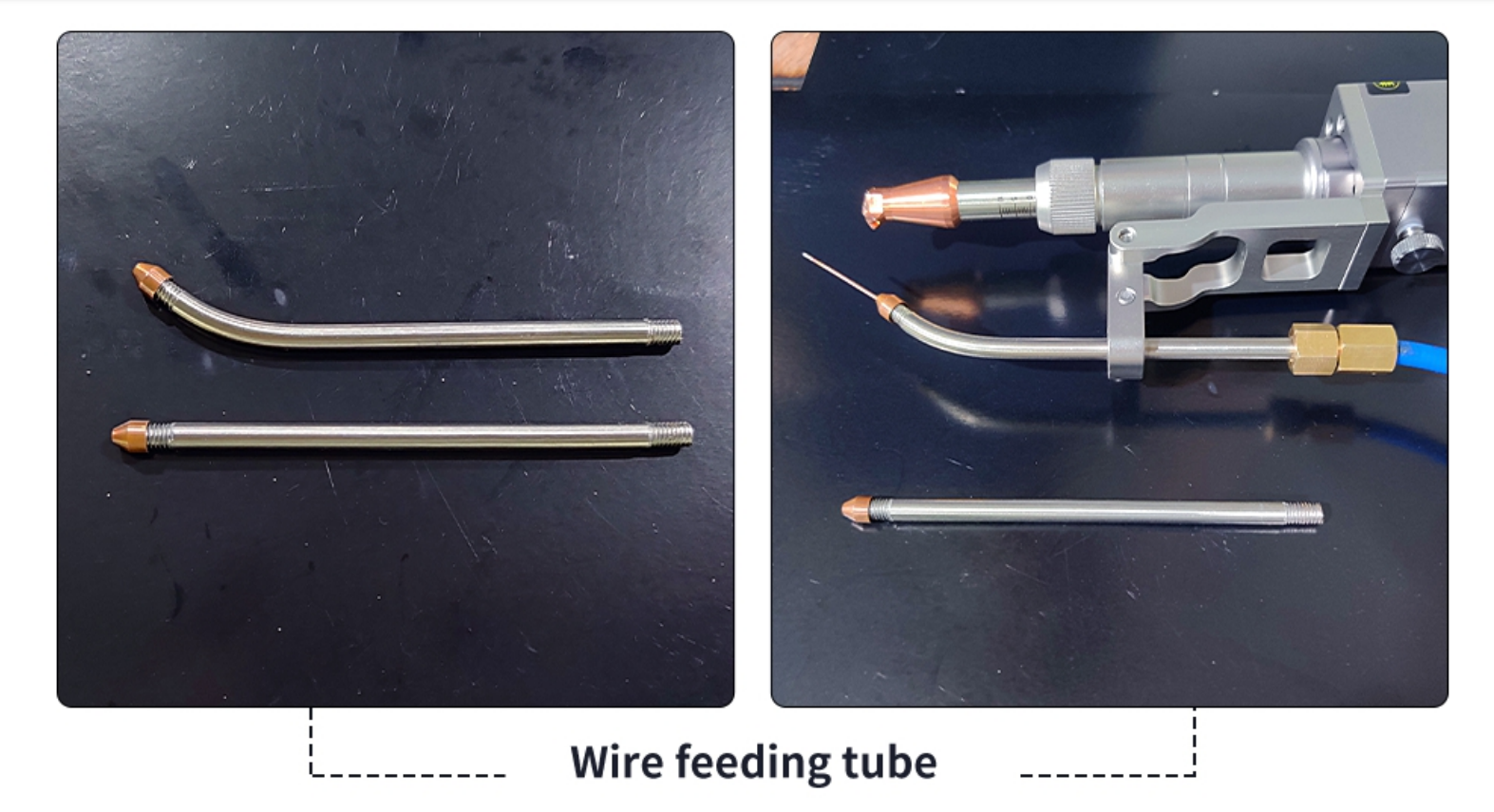

Handheld laser welding machine Accessories

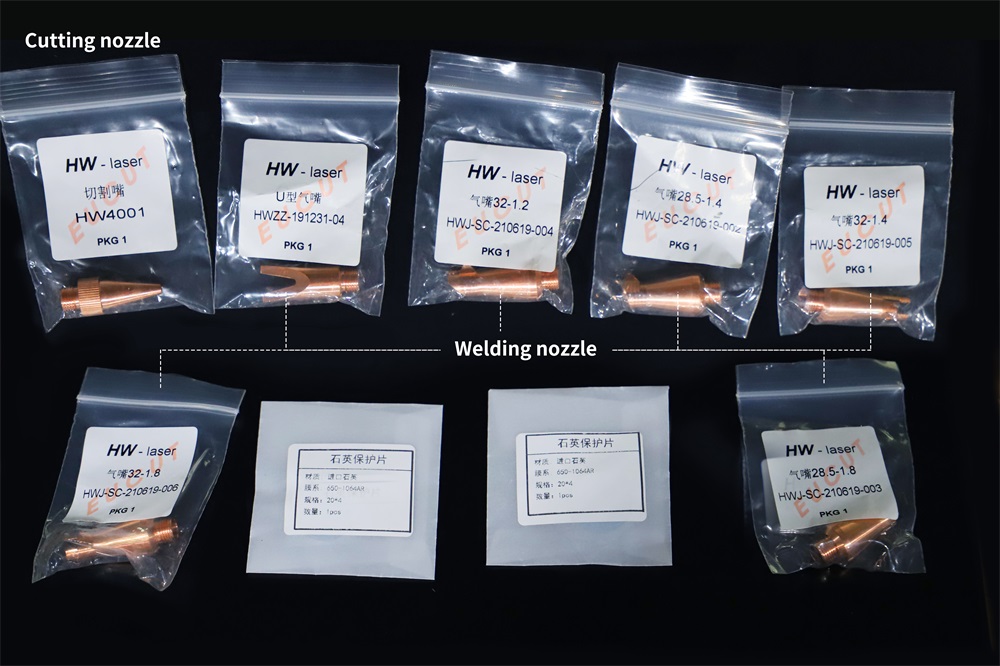

Here we introduce laser cutting nozzles

When we have a fiber handheld laser welder and replace the welding nozzle with a cutting nozzle, we can call it a handheld fiber laser welding and cutting machine. Isn't it a great name! !!!

It can take the optical fiber from the fiber laser and gather it to a tiny point to produce a high intensity laser for cutting purpose. However, please note that it is not able to cut too thick material. You can contact the sales person for details.

You can start by learning about the other parts of our fiber laser welders by looking at how does laser welding machine work.

|  English

English