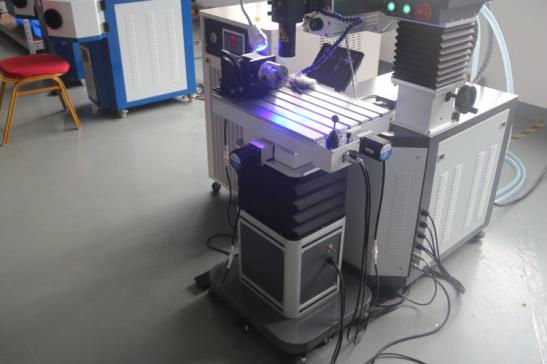

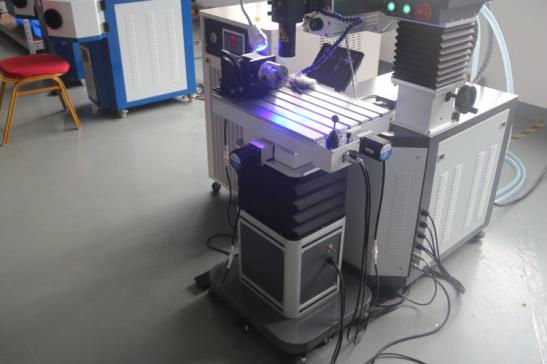

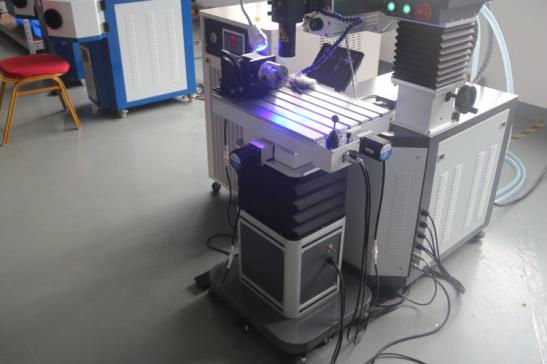

Mold Laser Welding Machine

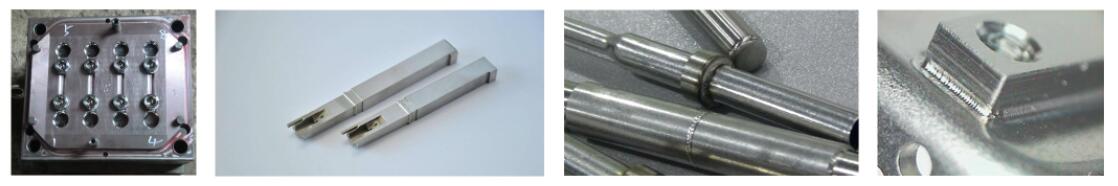

Widely used in die-casting molds, plastic molds, aluminum beryllium copper molds, small and medium-sized molds, extra large molds, sand holes, cracks, chipping angle and wear edging, sealing edges and other minor parts of the repair. The applicable base materials include: various die steel, stainless steel, beryllium copper, precious metal, extremely hard material, chain, jewelry, electronic components, sensors, precision machinery, communication, connectors, data lines, crafts, etc.

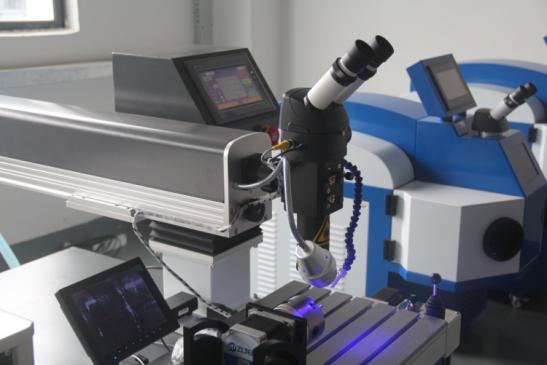

Following are the main parts of our Mold Laser Welding Machine

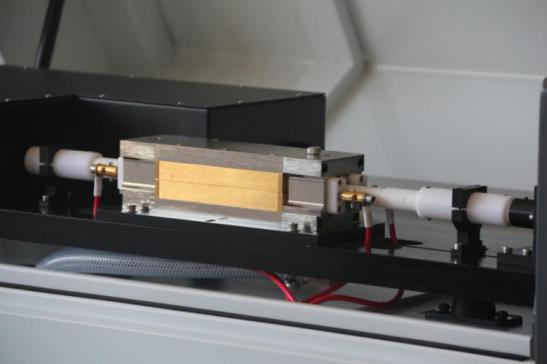

1. Xenon lamp

200W with single Xenon Lamp, 300W, 400W and 500W With double Xenon Lamp.

Original: China

Lifetime: 3,000,000 times,for example,work 8 hours per day,one lamp can use for 6 months at least.

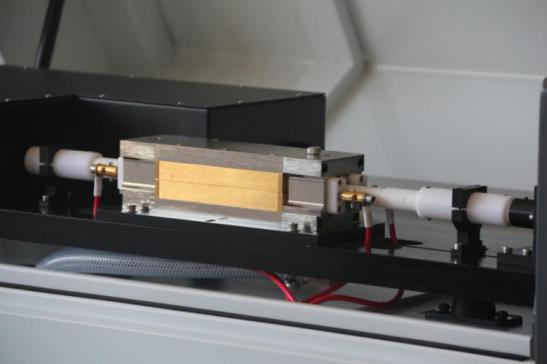

2. Laser crystal installs inside the metal cavity

a. High gain, High efficiency, and High optical quality

b.Low threshold, Low loss at 1.06um

c.Good thermal conductivity and thermal shock characteristics

d.Mechanical strength

e.Material characteristics allow for various modes of operation (CW, pulsed, Q-switched, mode-locked and cavity dumped)

3.The cavity

Inside with Xenon Lamp, ceramic core, etc

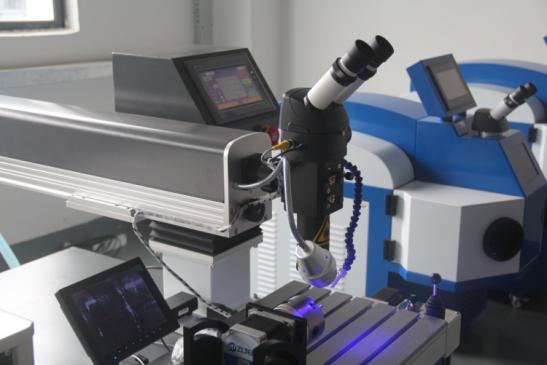

4.Touch screen

It used to adjust welding power, frequency, spot diameter, machine on and off, etc.

5.Working table

With electrical working table

X-axis: 250mm; Y-axis:200mm; Z-axis: 200mm;

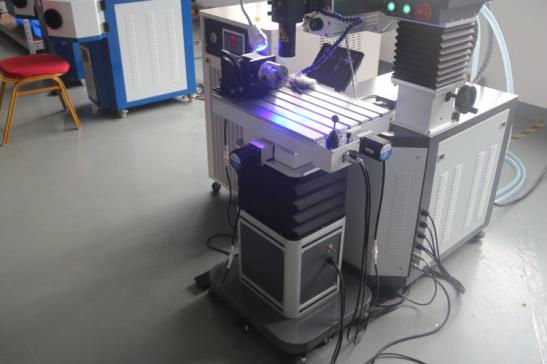

6.Water chiller

Use a digital LED controller with a faulty alarm, can learn the machine working situation quickly.

Provide an excellent cooling effect

The cooling system is easy to handle with stable performance

7.CCD camera

Can observe the welding effect very clearly.

English

English