Our mold laser welder supports customized trajectories

4 six laser welding machine & 4 six laser welding system

3 six laser welding machine & 3 six laser welding system

2 six laser welding machine & 2 six laser welding system

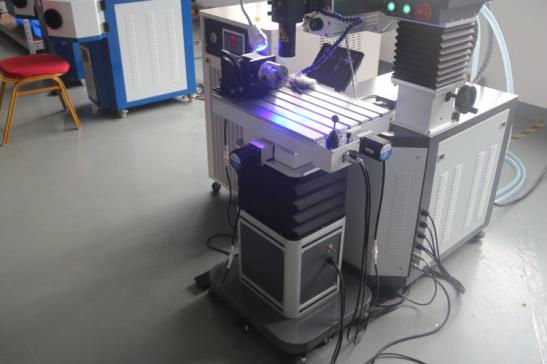

Mold Laser Welder

Extend the Life of Your Molds and Save

The most costly and difficult process in plastic manufacturing is the creation, maintenance, and repair of your molds. A defective mold can create losses in production, reputation, and revenue. But with the right equipment, you can keep your expensive molds in tip-top condition. A mold welder will save you the expense and time of sending a mold for repair. You can make the repairs yourself.

Mold Laser Welding Specifications

| Laser Power | 200W | 400W | 500W |

| Laser Type | YAG |

| Wavelength | 1064nm |

| Max Output Energy | 200W | 400W | 500W |

| Max Single Pulse Energy | 80J | 100J | 120J |

| Pulse Width | 0.1~20ms |

| Max Output Energy | 0~35HZ | 0~100HZ | 0~100HZ |

| Welding Depth | 0.1~2mm | 0.1~2.5mm | 0.1~3mm |

| Observation System | Microscope or CCD for option |

| Spot Size Adjustment Range | 0.1~3mm |

| Total Power Consumption | 6kw | 12kw | 14kw |

| Rated Power | AC220±5% ;50HZ | AC380±5% ;50HZ |

| Cooling Method | Water Cooling |

| Workbench Bearing | ≤200kg |

| Dimension of Worktable | Stroke of 3 axis: X axis 250mm, Y axis 150mm, Z axis 200mm (electric or manual for option) |

| Net Weight | 300kg |

| Machine Dimension | Main Machine:560*750*1170mm |

| (L*W*H) | Worktable:450*450*700mm

|

OPT-MW200W/ 300W/ 400W/ 500W series laser welder was originally designed for mold industry which used for welding and repairing die-casting molds, extrusion molds,round pipe, etc.

By using soldering wires, it used to fill the crack or blowholes and reuse the mold which saves production cost and improves working efficiency significantly. General laser mold welder also can be used in metal sheet stitching welding, pipe/ tube conjunction welding, and manufacturing of sensor, level switch, and fine auto parts, etc.

Optic Laser Welding Machine applies a high energy pulse to heat a specific tiny area of certain materials. Laser welding is a new type of welding technology, mainly on thin materials and precision components. It can achieve spot weld, butt weld, stitch weld, seal weld. Its advantages are high positional accuracy, being easy to realize robotization.

Easy of Use and Professional Results

Working with our friendly customer service team, you’ll quickly learn the ins and out’s of edge repair, hole repair, repair EDM pits, add material for shimming, tool repair, small weldments, and porosity repairs. we can also provide the equipment you need for identification engraving. With a mold laser welder, you’ll extend the life of your molds and save.

Advantages of mould laser welding machine:

Ability for molds to be repaired multiple times

Quicker repair of molds with much faster machining or bench time

Portable and flexible to reach almost any feature, even in large molds

Less expensive from a total-cost perspective and lasts longer

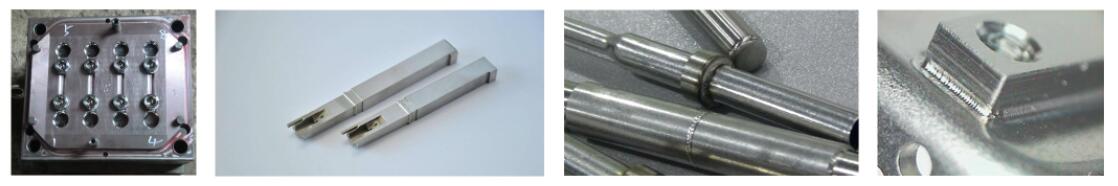

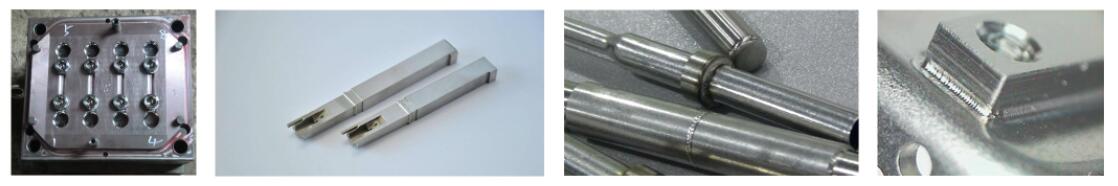

Mold samples welded by mold laser welding machine

1. Xenon lamp

200W with single Xenon Lamp, 300W, 400W and 500W With double Xenon Lamp.

Original: China

Lifetime: 3,000,000 times,for example,work 8 hours per day,one lamp can use for 6 months at least.

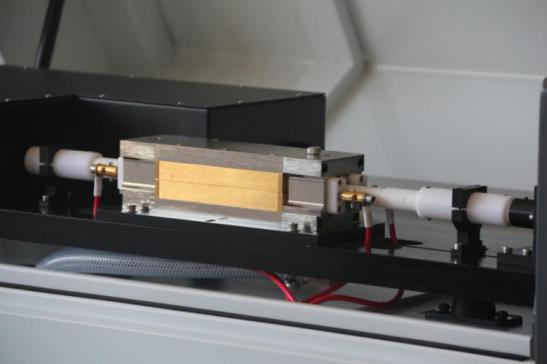

2. Laser crystal installs inside the metal cavity

a. High gain, High efficiency, and High optical quality

b.Low threshold, Low loss at 1.06um

c.Good thermal conductivity and thermal shock characteristics

d.Mechanical strength

e.Material characteristics allow for various modes of operation (CW, pulsed, Q-switched, mode-locked and cavity dumped)

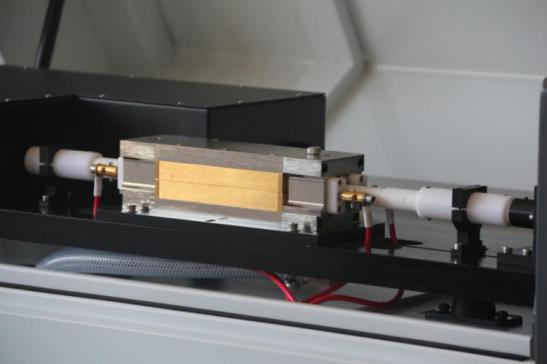

3.The cavity

Inside with Xenon Lamp, ceramic core, etc

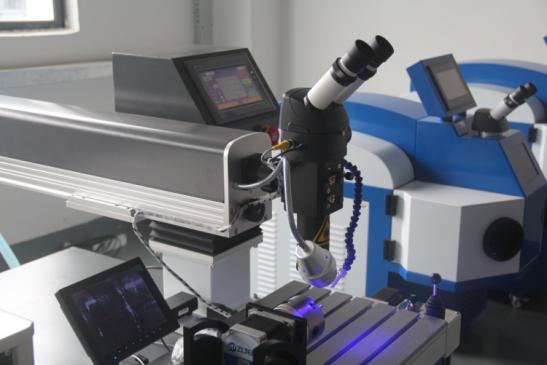

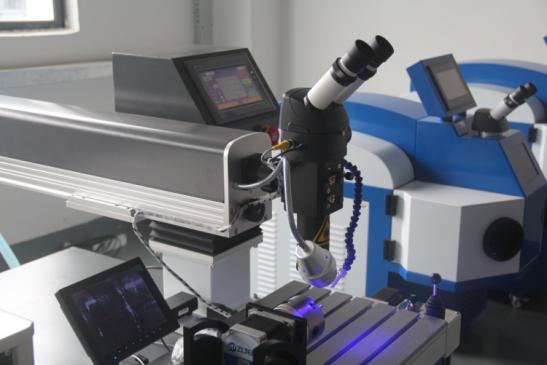

4.Touch screen

It used to adjust welding power, frequency, spot diameter, machine on and off, etc.

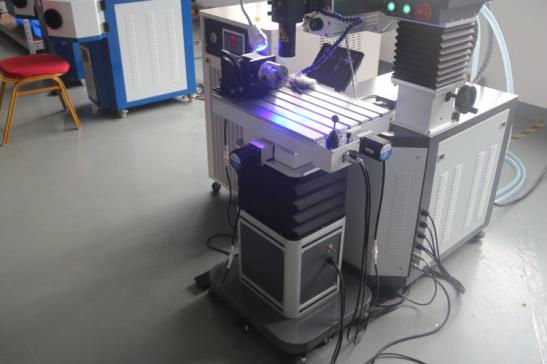

5.Working table

With electrical working table

X-axis: 250mm; Y-axis:200mm; Z-axis: 200mm;

6.Water chiller

Use a digital LED controller with a faulty alarm, can learn the machine working situation quickly.

Provide an excellent cooling effect

The cooling system is easy to handle with stable performance

7.CCD camera

Can observe the welding effect very clearly.

English

English