| Machine Type | OPT-T160 | OPT-T220 | OPT-T230 | OPT-T350 |

| Laser Power | ≤2000W | ≤2000W | ≤3000W | ≤3000W |

| Cutting Length | 3M/6M | 3M/6M | 6M/9.2M | 6M/9.2M |

| Clamping Range | Ø10- Ø350 |

| Re-positioning Accuracy | ±0.03mm |

| Axial Positioning Accuracy | ±0.05mm/m |

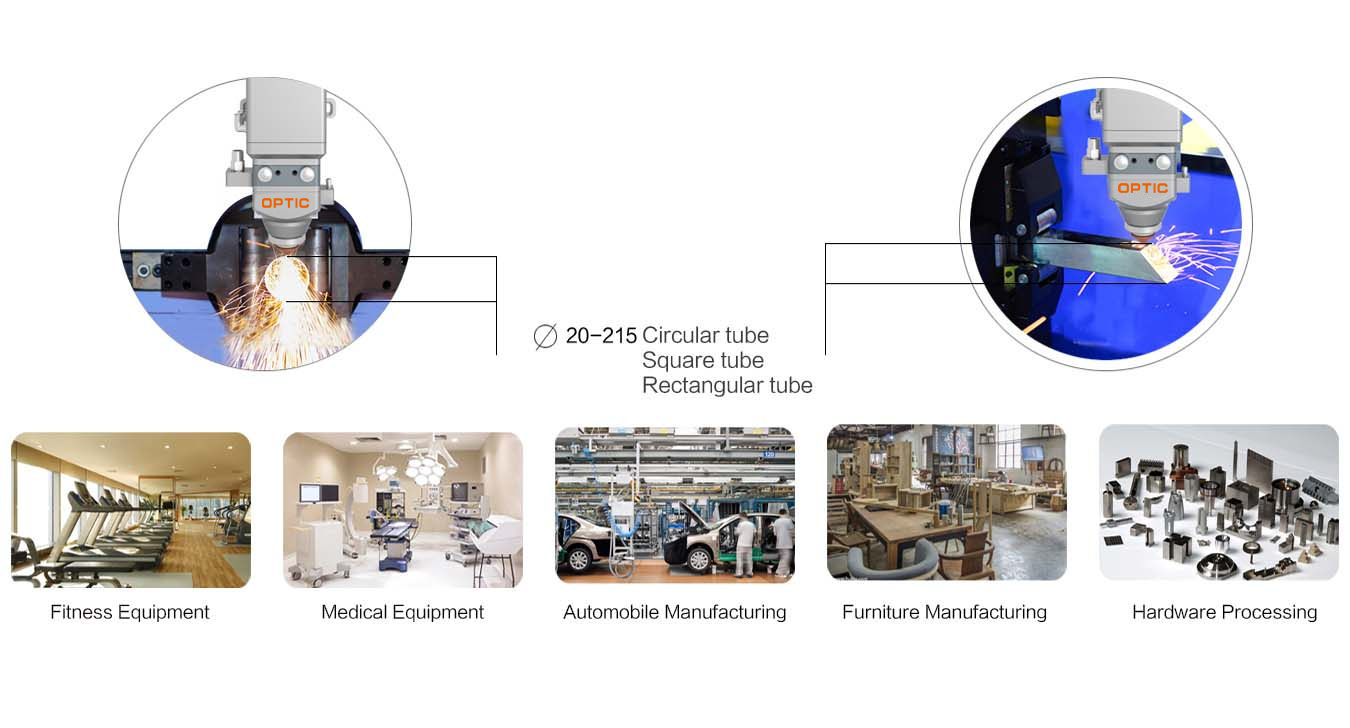

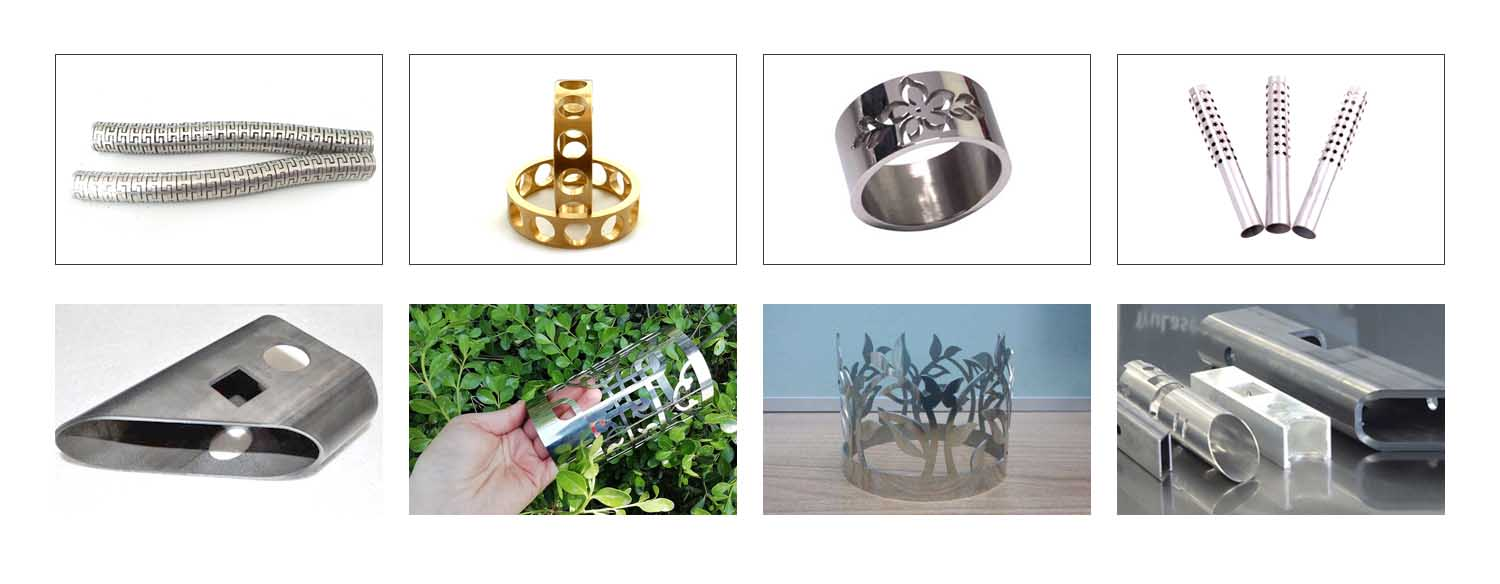

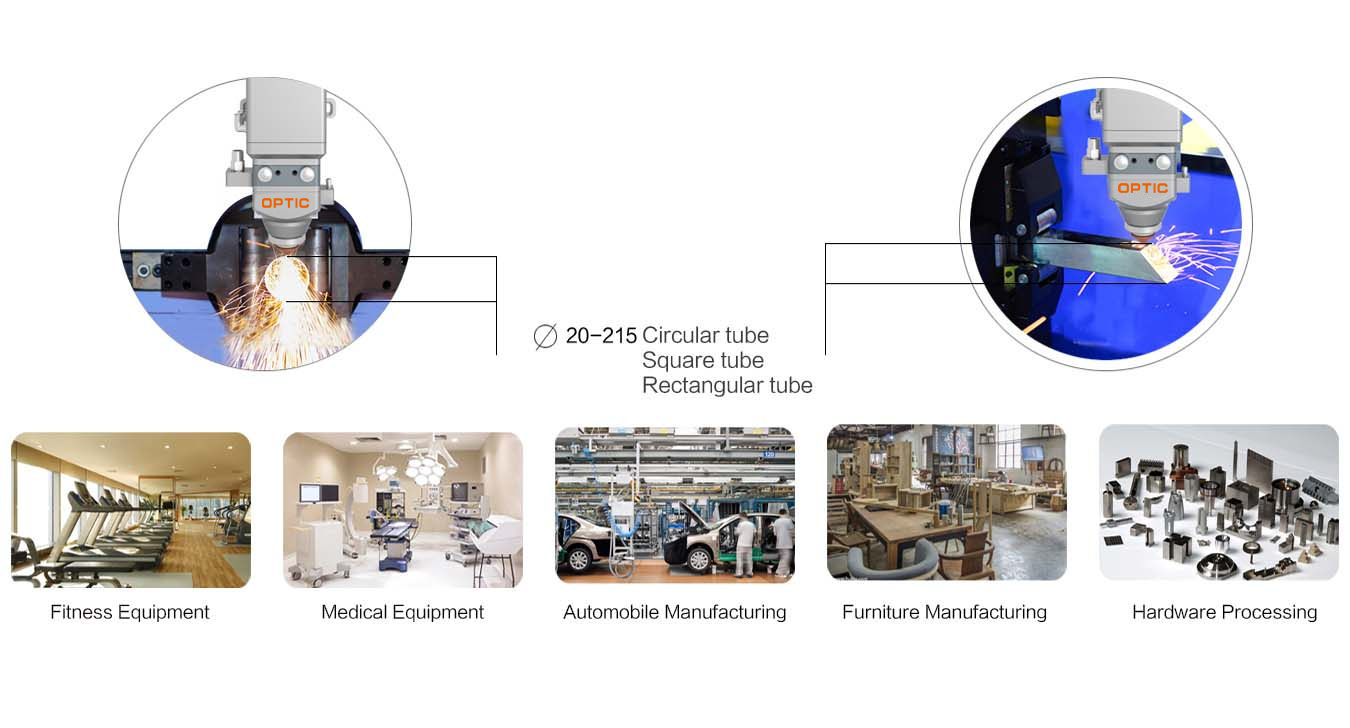

1.Applicable for metal pipe,square pipe,rectangular pipe,deformed pipe ect ,with fast speed and high quality

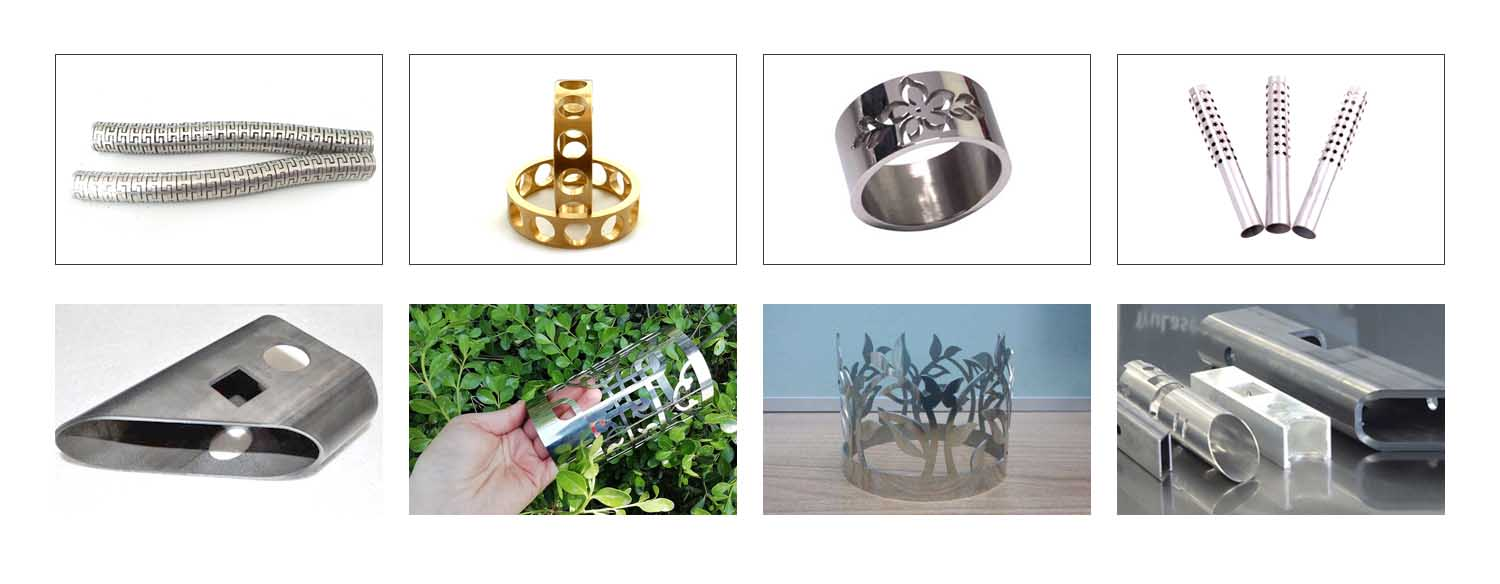

2.Smaller cutting gap,low deformation,more smooth、flat and beautiful cutting edge,and without secondly process.High-accuracy cutting to cut down consumption effectively

3.Automatically moistening guide rail,both pneumatically back and forward chucks,quickly responding in the corner to improving cutting efficiency tremendously

4. Tube laser cutting machine adopts an electric clamp design on both sides and it can modulate the center automatically

1.Stability and reliability of light path system and control system.

2.Imported original fiber lasers,high and stable function,lifespan is over 100000 hours.

3.Higher cutting quality and efficiency ,cutting speed is up to 80m/min with appearance and beautiful cutting edge.

4.German high performance reducer,gear and rack;Japanese guide and all screw.

English

English