The first high-precision glass cutting machine. Compared with Amazon's glass laser cutting machine and Alibaba's glass laser cutting machine, our cutting machine will have faster-cutting efficiency, higher precision, and faster efficiency due to its size.

He is more suitable for glass manufacturers! !!

Glass cutting We are professional! !!

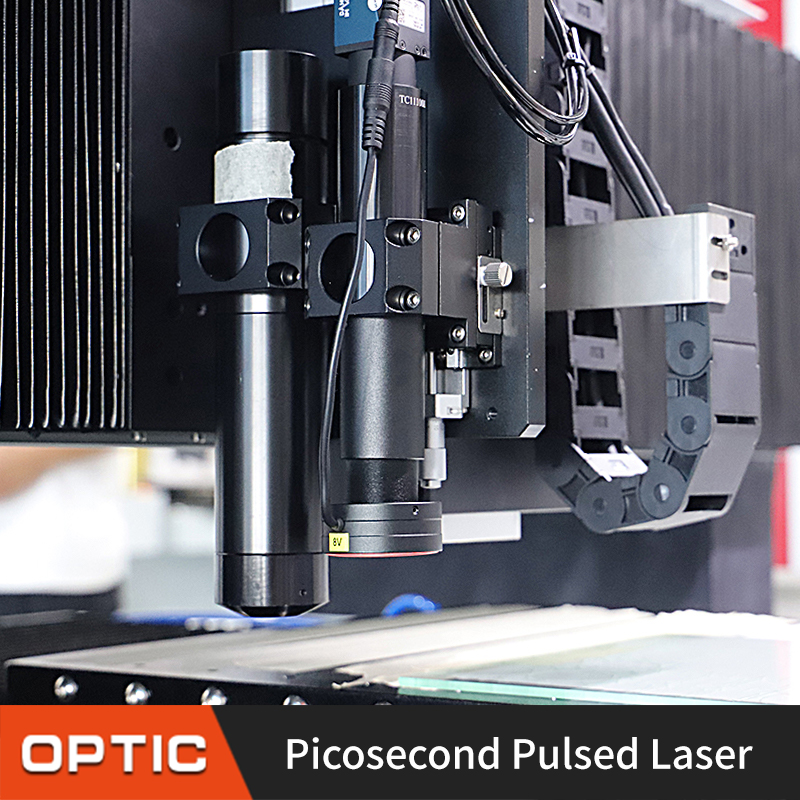

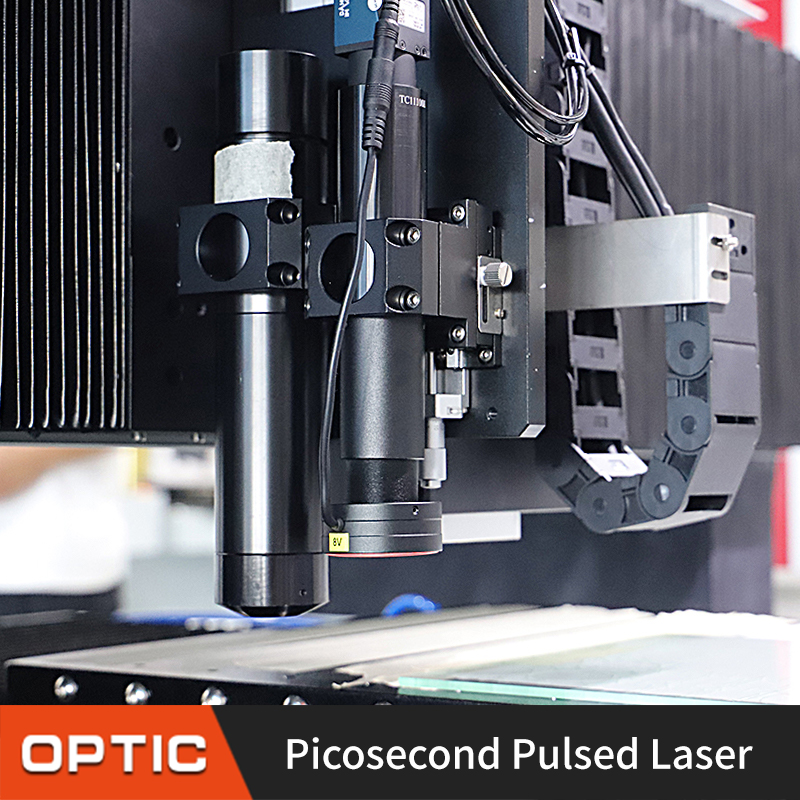

Glass Laser Cutting Machine Product Parameters | Laser type | Picosecond Pulsed Laser |

| Laser power | 10w - 100w |

| Laser wavelength | 1060nm |

| Pulse frequency | 1Hz - 1000kHz |

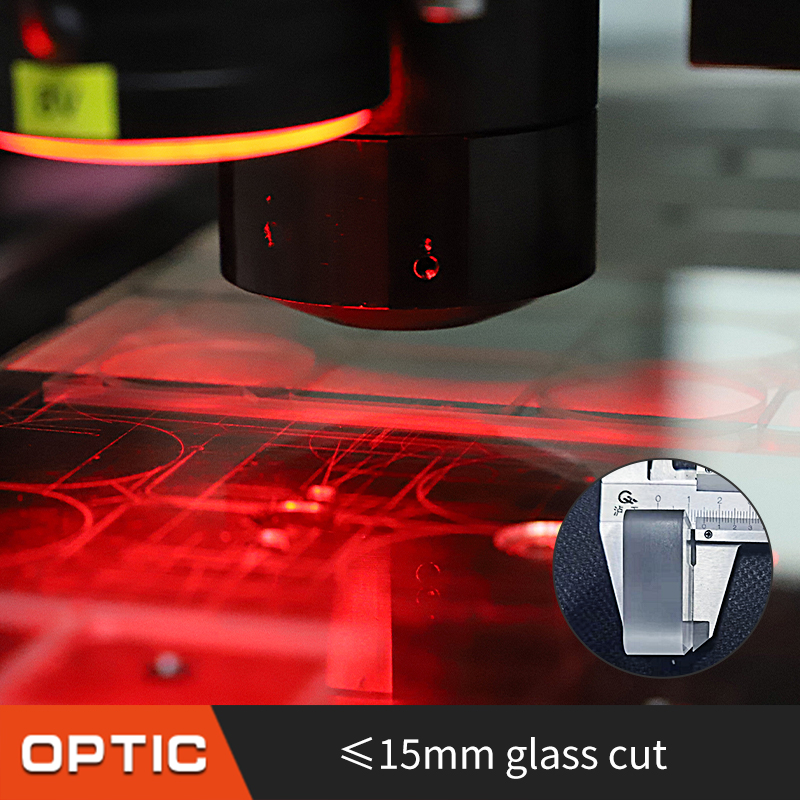

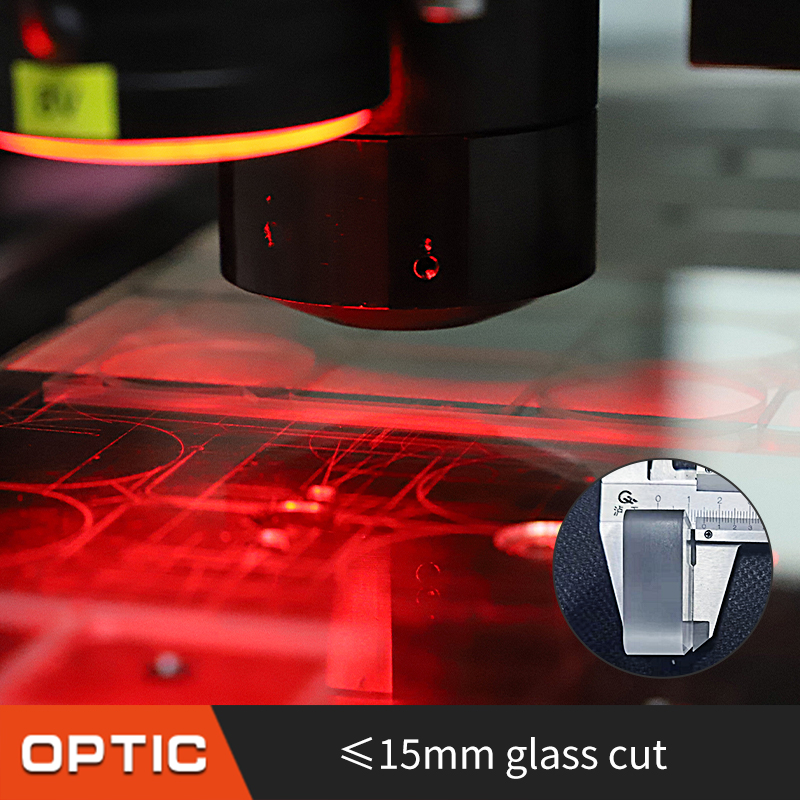

| Cutting thickness | ≤10mm |

| Cutting speed | 0-300mm/s adjustable |

| Cutting accuracy | ≤±20um , The highest accuracy is ± 5um |

X/Y stroke

| 500×650mm |

| Weight | About 2000kg |

| Warranty service | 1 year |

| Power supply | AC220V±5% |

| Cooling method | Water cooling |

| Length,width,height | 1568/1550/1800(mm) |

Glass Laser Cutting thickness schedule | Laser power | Frequency | Cutting thickness | Cutting speed |

| 10w | 100k | ≤0.7mm | ≤500mm/s |

| 20w | 100k | ≤1.5mm | ≤500mm/s |

| 30w | 50k | ≤4.5mm | ≤300mm/s |

| 50w | 20k | ≤15mm | ≤120mm/s |

| 80w | 50k | ≤10mm | ≤300mm/s |

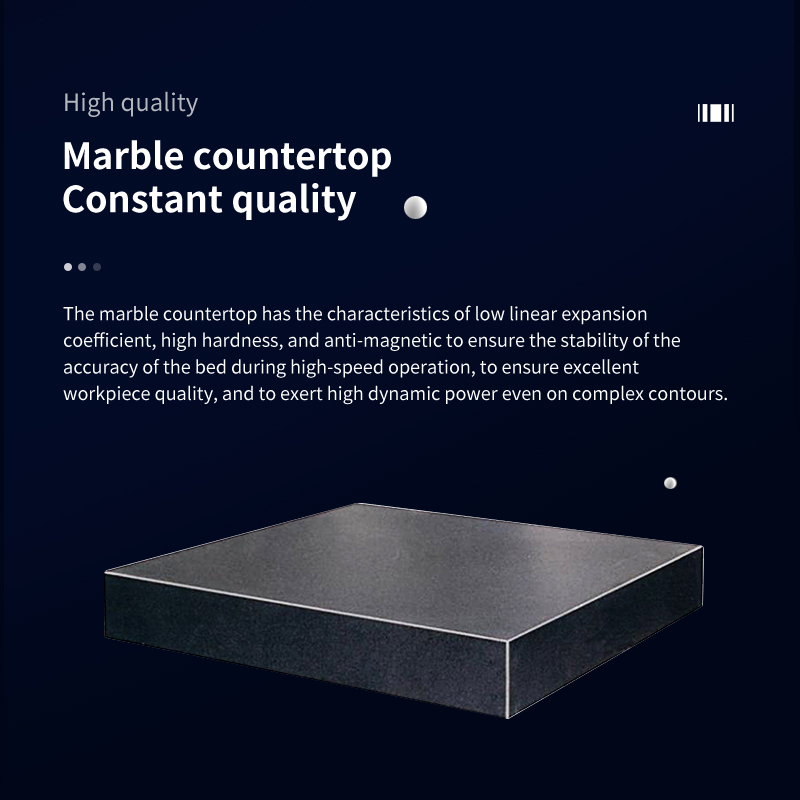

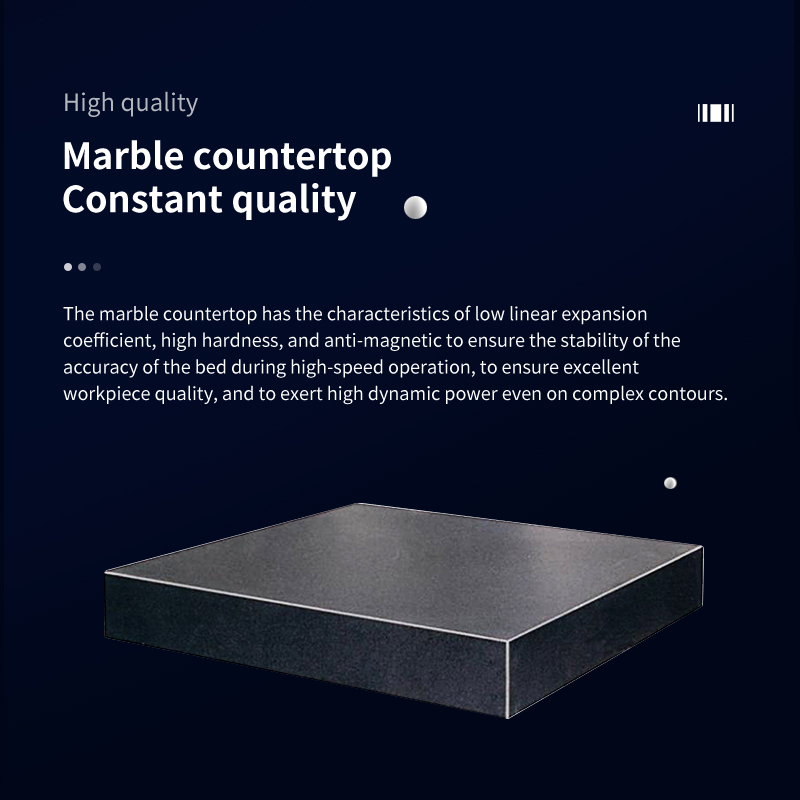

MARBLE COUNTERTOPCONSTANT QUALITY

The marble countertop has the characteristics of low linear expansion coefficient, high hardness, and anti-magnetic to ensure the stability of the accuracy of the bed during high-speed operation, to ensure excellently

workpiece quality, and to exert high dynamic power even on complex contours.

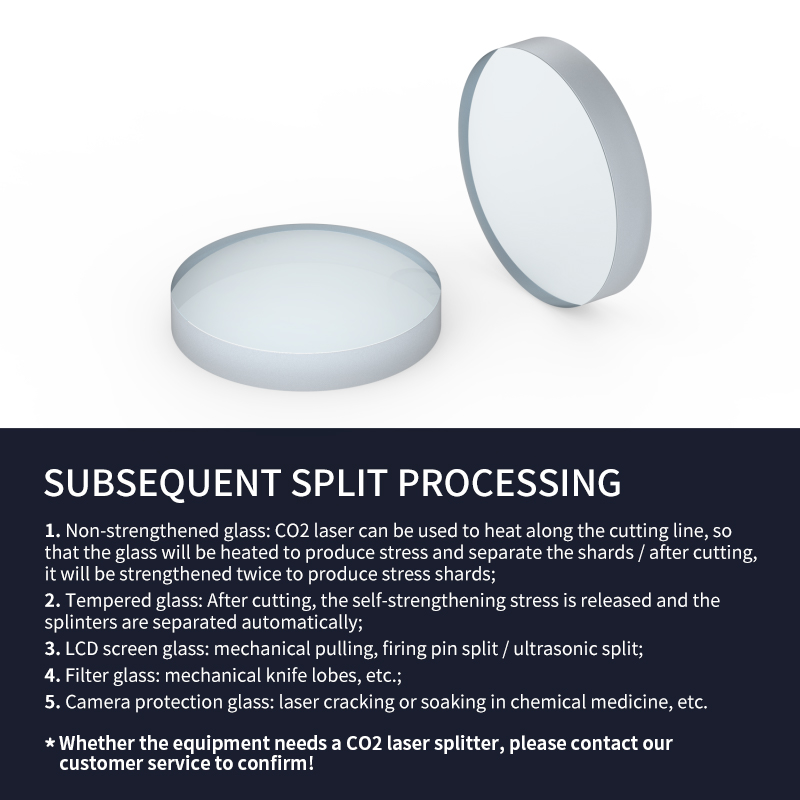

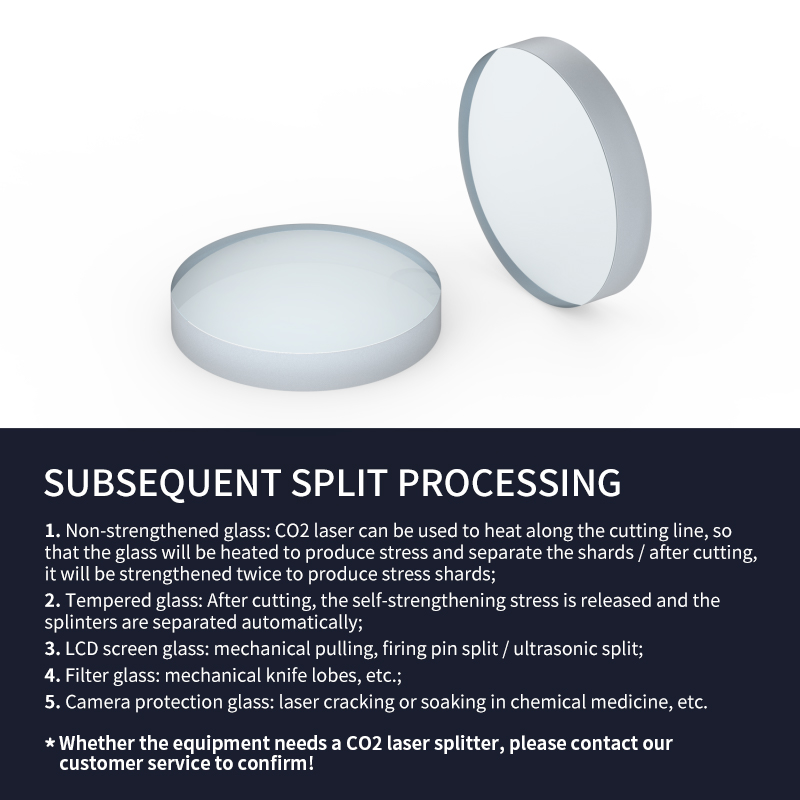

SUBSEQUENT SPLIT PROCESSING

1. Non-strengthened glass: CO2 laser can be used to heat along the cutting line, so that the glass will be heated to produce stress and separate the shards / after cutting, it will be strengthened twice to produce stress shards;

2. Tempered glass: After cutting, the self-strengthening stress is released and the splinters are separated automatically;

3. LCD screen glass: mechanical pulling, firing pin split / ultrasonic split;

4. Filter glass: mechanical knife lobes, etc.;

5. Camera protection glass: laser cracking or soaking in chemical medicine, etc.

* Whether the equipment needs a co2 laser splitter, please contact our customer service to confirm!

GLASS LASER CUTTING HEAD

GLASS LASER CUTTING WORK AREA

English

English