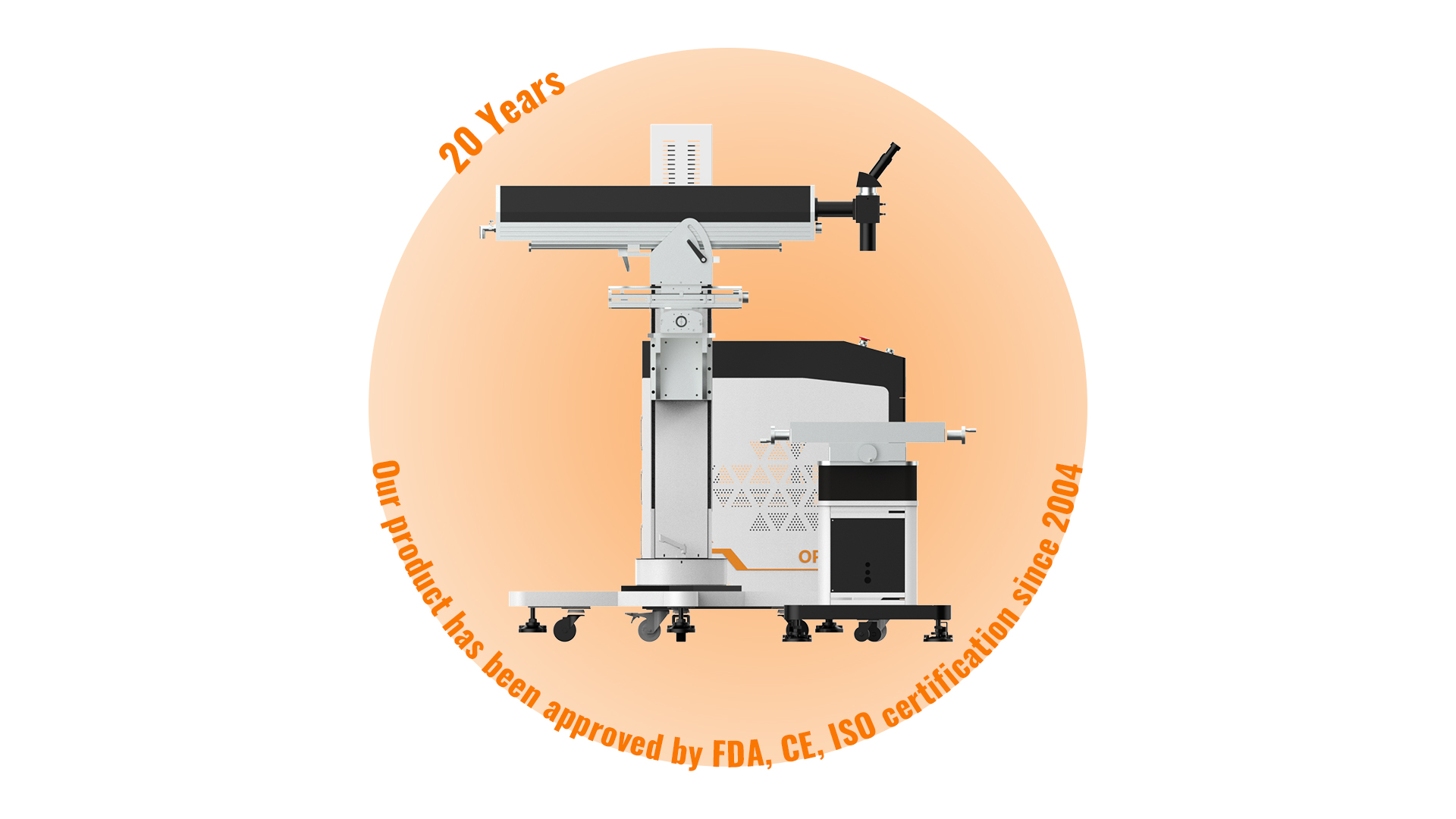

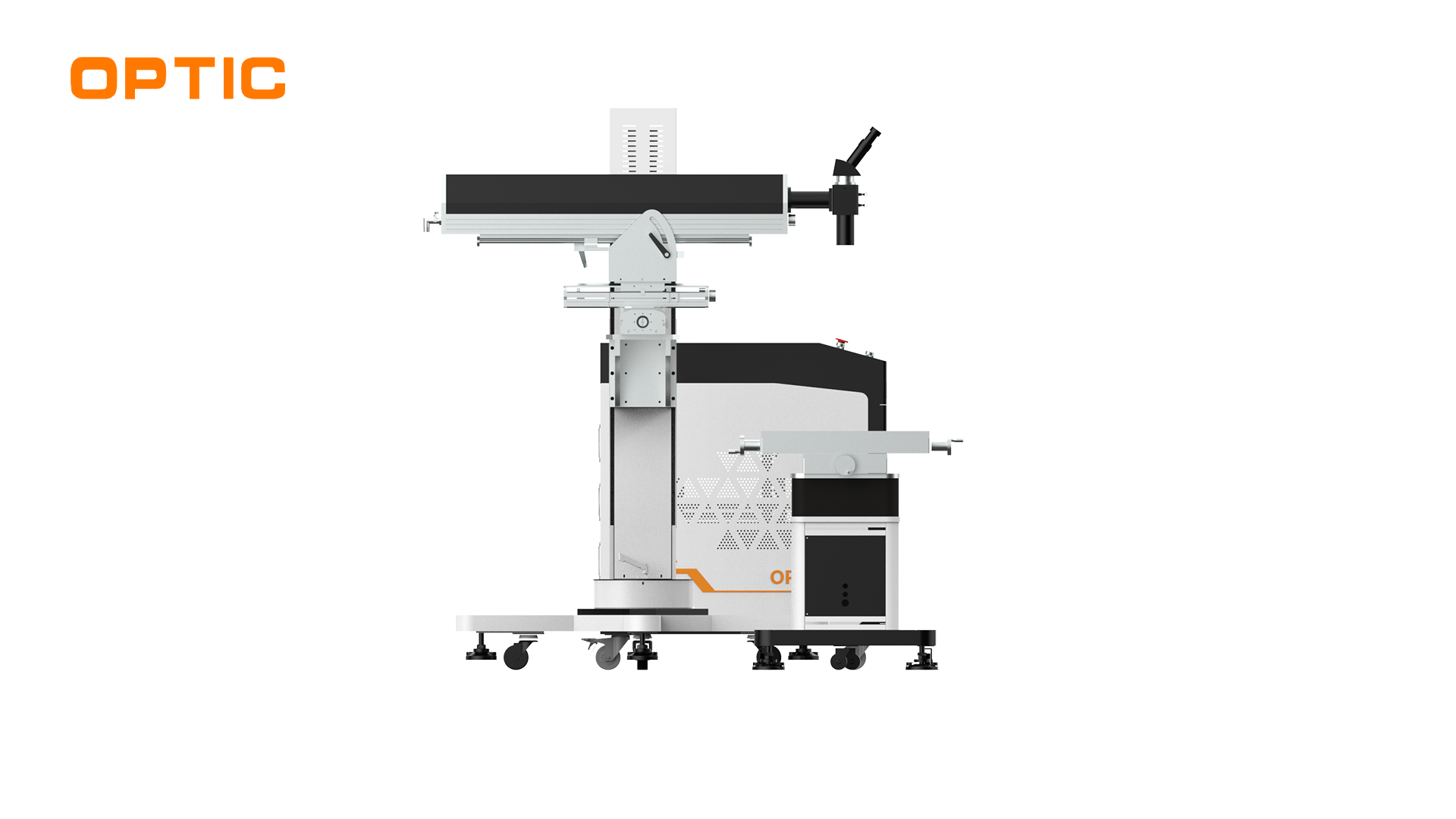

mold repair laser welding machine Parameters

| Laser Power | 200W | 400W | 500W |

| Laser Type | YAG |

| Wavelength | 1064nm |

| Max Output Energy | 200W | 400W | 500W |

| Max Single Pulse Energy | 80J | 100J | 120J |

| Pulse Width | 0.1~20ms |

| Max Output Energy | 0~35HZ | 0~100HZ | 0~100HZ |

| Welding Depth | 0.1~2mm | 0.1~2.5mm | 0.1~3mm |

| Observation System | Microscope or CCD for option |

| Spot Size Adjustment Range | 0.1~3mm |

| Total Power Consumption | 6kw | 12kw | 14kw |

| Rated Power | AC220±5% ;50HZ | AC380±5% ;50HZ |

| Cooling Method | Water Cooling |

| Control device | Industrial Control Dedicated joystick |

| Workbench Bearing | ≤200kg |

| Dimension of Worktable | Stroke of 3 axis: X axis 250mm, Y axis 150mm, Z axis 200mm (electric or manual optional) |

| Net Weight | 450kg |

| Machine Dimension(L*W*H) | Cantilever lifting platform:910*520*825mm

Main Machine:1320*660*1100mm

Worktable:450*450*700mm |

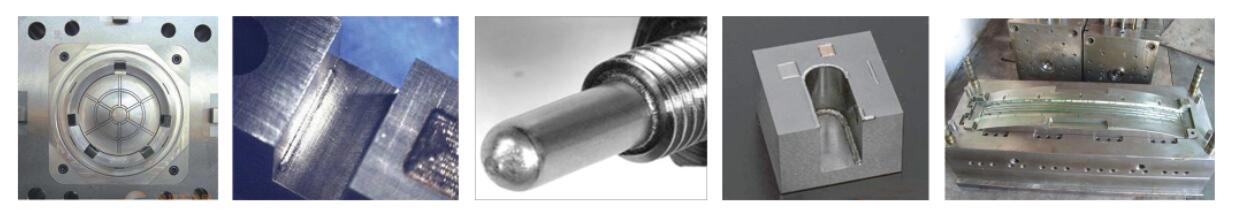

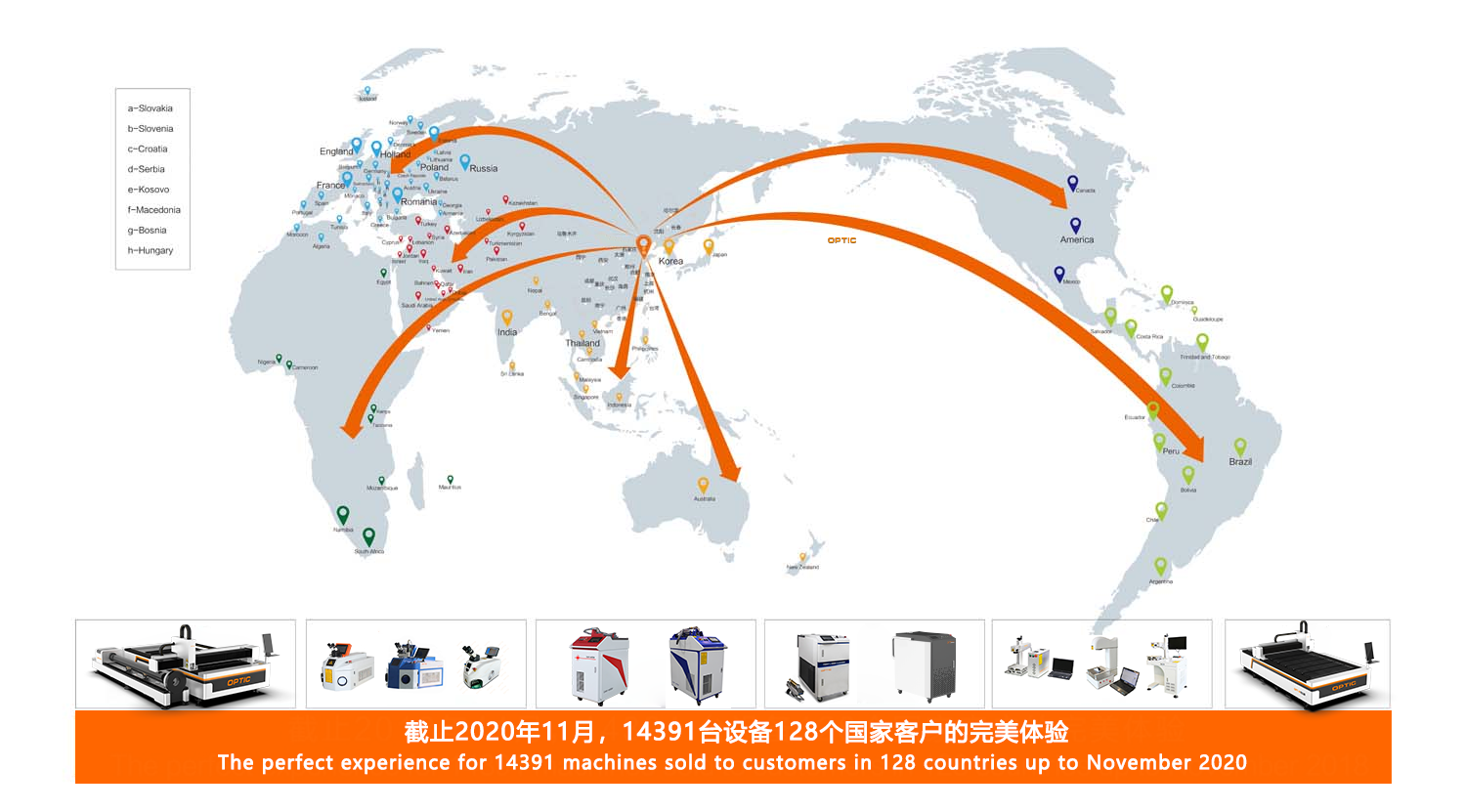

Range of Application

Widely used in die-casting molds, plastic molds, aluminum beryllium copper molds, small and medium-sized molds, extra large molds, sand holes, cracks, chipping angle and wear edging, sealing edges and other minor parts of the repair.

The applicable base materials: various die steel, stainless steel, beryllium copper, precious metal, extremely hard material, chain, jewelry, electronic components, sensors, precision machinery, communication, connectors, data lines, crafts, etc.

mold repair laser welding machine Characteristics

1、Adopt Germany imported metal cavity, corrosion resistance, high temperature resistance, cavity life (8-10) years, xenon lamp life more than 8 million times

2、Uses the world's most advanced automatic shading system to eliminate eye irritation during working hours

3、10X microscope magnification, cross-cursor knowledge, and automatic light shading with high-speed liquid crystal light valve. The protective gas output in synchronization with the laser will ensure the appearance of solder joints and the solder joints will not oxidize and discolor

4、The display adopts 7-inch LED screen, which can realize the free conversion in English and Chinese, and can be connected with the international market; CCD monitoring system can be installed

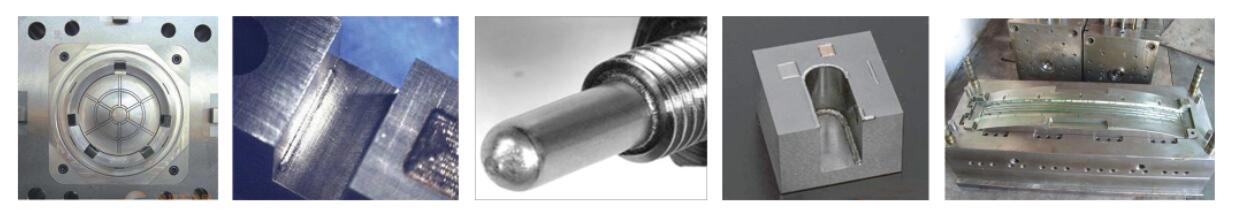

5、Large welding depth, firm and beautiful appearance, full melting, no traces, no bulges or dents

6、Small heat-affected zone, won’t cause deformation of the mold

Samples

English

English